Ngaphakathi kwikhonkco lokubonelela, abanye oomlingo bajika isanti ukuba ibe ziidiski ze-silicon zekristale ezakhiwe ngedayimane, eziyimfuneko kulo lonke unikezelo lwesemiconductor. Bayinxalenye yekhonkco lokubonelela nge-semiconductor elonyusa ixabiso "lesanti ye-silicon" phantse izihlandlo eziliwaka. Ukukhanya okufipheleyo okubona elunxwemeni yisilicon. I-Silicon yikristale eyinkimbinkimbi kunye ne-brittleness kunye nesinyithi esiqinileyo (izakhiwo zetsimbi kunye nezingezo zetsimbi). I-silicon ikhona kuyo yonke indawo.

I-silicon yinto yesibini eqhelekileyo eMhlabeni, emva kwe-oksijini, kunye neyesixhenxe eyona nto ixhaphakileyo kwindalo yonke. I-Silicon yi-semiconductor, oku kuthetha ukuba ineempawu zombane phakathi kwee-conductor (ezifana nobhedu) kunye ne-insulators (ezifana neglasi). Isixa esincinci seeathom zangaphandle kwisakhiwo se-silicon sinokutshintsha ngokusisiseko ukuziphatha kwayo, ngoko ke ukucoceka kwesilicon ye-semiconductor-grade kufuneka kuphakame ngokumangalisayo. Ubuncinci bokucoceka okwamkelekileyo kwi-silicon yebakala le-elektroniki yi-99.999999%.

Oku kuthetha ukuba i-athom enye kuphela engeyo-silicon evumelekileyo kwi-athom nganye yeebhiliyoni ezilishumi. Amanzi okusela alungileyo avumela izigidi ezingama-40 zeemolekyuli ezingezizo zamanzi, eziphindwe kabini ezizigidi ezingama-50 ngaphantsi kwe-silicon ye-semiconductor-grade.

Abavelisi be-silicon engenanto kufuneka baguqule isilicon ecocekileyo ibe yikristale enye. Oku kwenziwa ngokuzisa ikristale engumama omnye kwisilicon etyhidiweyo kwiqondo lobushushu elifanelekileyo. Njengoko iikristale zentombi entsha ziqala ukukhula zijikeleze ikristale kamama, i-silicon ingot ihamba kancinci ukusuka kwisilicon etyhidiweyo. Inkqubo icotha kwaye ingathatha iveki. I-silicon ingot egqityiweyo inobunzima obumalunga neekhilogram ezili-100 kwaye inokwenza ngaphezulu kwama-3,000 amaqebengwana.

Amaqhekezana asikwa abe ziziqwenga ezibhityileyo kusetyenziswa ucingo lwedayimani olucoleke kakhulu. Ukuchaneka kwezixhobo zokusika i-silicon kuphezulu kakhulu, kwaye abaqhubi kufuneka bahlale bebekwe esweni, okanye baya kuqalisa ukusebenzisa izixhobo zokwenza izinto ezingenangqondo kwizinwele zabo. Intshayelelo emfutshane ekuvelisweni kwee-wafers zesilicon yenziwe lula kakhulu kwaye ayiniki tyala ngokupheleleyo igalelo leengcaphephe; kodwa sinethemba lokubonelela ngemvelaphi yokuqonda nzulu kweshishini le-silicon wafer.

Ubudlelwane bokubonelela kunye nokufunwa kwee-silicone wafers

Imakethi ye-silicon wafer ilawulwa ziinkampani ezine. Ixesha elide, imarike ikwi-balance balance phakathi kokubonelela kunye nemfuno.

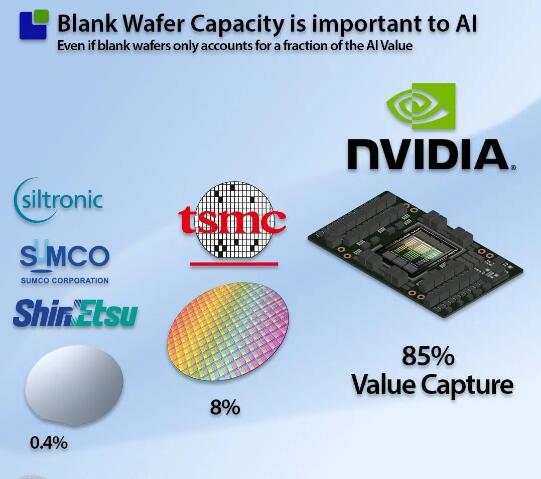

Ukwehla kwentengiso ye-semiconductor ngo-2023 kukhokelele ekubeni imarike ibekwimeko yokubonelela ngokugqithisileyo, okubangela ukuba uluhlu lwempahla lwangaphakathi nangaphandle lwabavelisi beetshiphu lube phezulu. Noko ke, le yimeko nje yokwexeshana. Njengoko imarike ibuyela, ishishini liza kubuyela ngokukhawuleza kumda womthamo kwaye kufuneka lihlangabezane neemfuno ezongezelelweyo eziziswe yi-AI revolution. Ukutshintshwa kwi-architecture ye-CPU yendabuko ukuya kwi-computing ekhawulezayo kuya kuba nefuthe kuwo wonke ishishini, njengoko Nangona kunjalo, oku kunokuba nefuthe kumacandelo aphantsi kwexabiso leshishini le-semiconductor.

IYunithi yoLungiso lweMizobo (GPU) yokwakha ifuna indawo yesilicon engaphezulu

Njengoko imfuno yokusebenza isanda, abavelisi beGPU kufuneka boyise imida ethile yoyilo ukuze baphumeze ukusebenza okuphezulu kwiiGPU. Ngokucacileyo, ukwenza i-chip ibe nkulu yindlela enye yokufezekisa ukusebenza okuphezulu, njengoko ii-electron zingathandi ukuhamba imigama emide phakathi kwee-chips ezahlukeneyo, ezithintela ukusebenza. Nangona kunjalo, kukho umda osebenzayo wokwenza i-chip ibe nkulu, eyaziwa ngokuba yi "retina limit".

Umda we-lithography ubhekisela kubukhulu obukhulu be-chip enokuthi ibonakaliswe kwisinyathelo esisodwa kumatshini we-lithography osetyenziselwa ukuveliswa kwe-semiconductor. Lo mda unqunywe ngubukhulu bobukhulu bomhlaba wemagnethi wesixhobo se-lithography, ngakumbi i-stepper okanye i-scanner esetyenziswe kwinkqubo ye-lithography. Kwitekhnoloji yamva nje, umda wemaski uhlala ujikeleze i-858 yeemilimitha zesikwere. Lo mda wesayizi ubaluleke kakhulu kuba umisela indawo ephezulu enokuthi ifaniswe kwi-wafer kwi-exposure eyodwa. Ukuba i-wafer inkulu kunomda, ukubonakaliswa okuphindaphindiweyo kuya kufuneka ukwenza ipateni epheleleyo ye-wafer, engenakwenzeka kwimveliso yobuninzi ngenxa yobunzima kunye nemingeni yokulungelelanisa. I-GB200 entsha iya kunqoba lo mda ngokudibanisa i-chip substrates ezimbini kunye nemilinganiselo yobungakanani besuntswana kwi-silicon interlayer, yenze i-super-particle-limited substrate ephindwe kabini. Eminye imida yentsebenzo sisixa sememori kunye nomgama kuloo memori (okt i-bandwidth yememori). Uyilo olutsha lwe-GPU loyisa le ngxaki ngokusebenzisa imemori egciniweyo ye-bandwidth ephezulu (HBM) efakwe kwi-silicon interposer efanayo kunye neechips ezimbini ze-GPU. Ukusuka kumbono we-silicon, ingxaki nge-HBM kukuba isuntswana ngalinye le-silicon liphindwe kabini kune-DRAM yemveli ngenxa yojongano oluphezulu olufunekayo kwi-bandwidth ephezulu. I-HBM ikwadibanisa i-logic yokulawula i-chip kwisitaki ngasinye, inyusa indawo ye-silicon. Ubalo olurhabaxa lubonisa ukuba indawo ye-silicon esetyenziswa kwi-2.5D GPU uyilo yi-2.5 ukuya kumaxesha e-3 ye-architecture yendabuko ye-2.0D. Njengoko bekutshiwo ngaphambili, ngaphandle kokuba iinkampani ezisisiseko zilungiselelwe olu tshintsho, umthamo we-silicon wafer unokuqina kakhulu kwakhona.

Umthamo wexesha elizayo wemarike ye-silicon wafer

Owokuqala kwimithetho emithathu yokwenziwa kwe-semiconductor kukuba eyona mali ininzi ifuna ukutyalwa xa kukho imali encinane ekhoyo. Oku kungenxa yendalo yomjikelo weshishini, kwaye iinkampani zesemiconductor zinobunzima bokulandela lo mgaqo. Njengoko kubonisiwe kulo mzobo, uninzi lwabavelisi be-silicone wafer baqaphela impembelelo yolu tshintsho kwaye baphantse baphinda kathathu inkcitho yabo yekota eyinkunzi kwiikota ezimbalwa ezidlulileyo. Nangona iimeko zeemarike ezinzima, oku kusenjalo. Eyona nto inomdla ngakumbi kukuba lo mkhwa kudala uqhubeka. Iinkampani zeSilicon wafer zinethamsanqa okanye zazi into abanye abangayaziyo. Ikhonkco lokubonelela nge-semiconductor ngumatshini wexesha onokuqikelela ikamva. Ikamva lakho lisenokuba lixesha elidlulileyo lomnye umntu. Nangona singasoloko sifumana iimpendulo, phantse sisoloko sifumana imibuzo efanelekileyo.

Ixesha lokuposa: Jun-17-2024